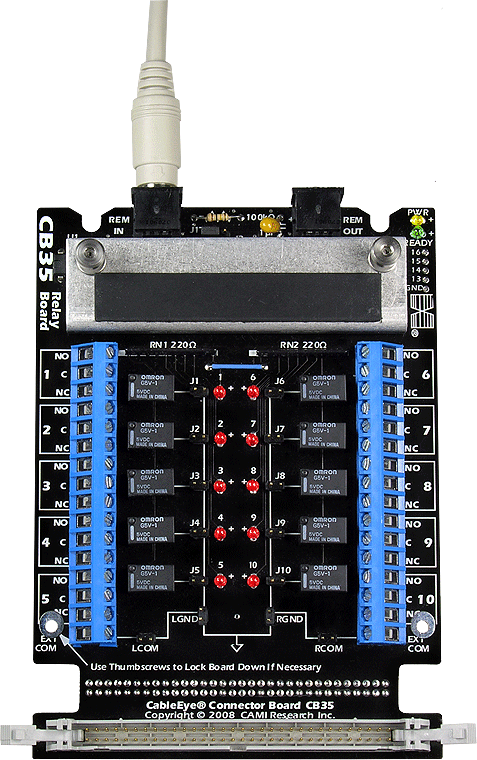

Enhancing Test Automation: CB35/R Relay Board Applications

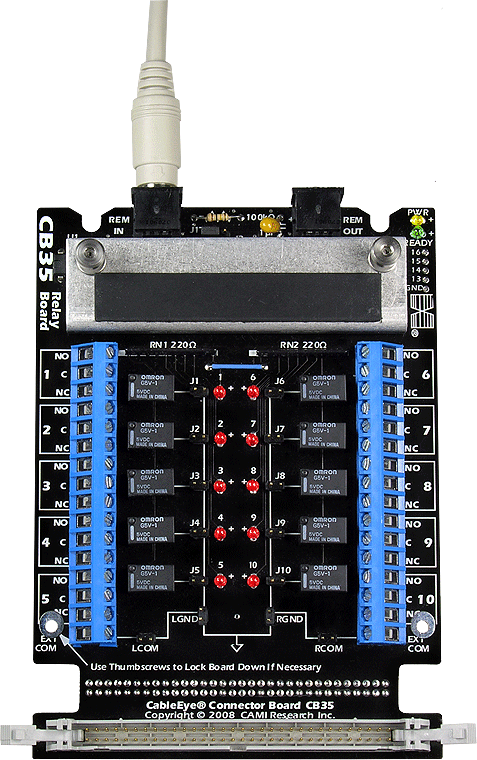

Powered by Macros or JavaScript commands, a single CB35/R relay board makes it easy to control multiple external devices and automate multiple circuit switching across your test and production environment. Simply cascade relay boards for expanded i/o control options.

Its most popular application by far, is switching circuits directly within the Article Under Test (AUT). But the CB35/R goes far beyond that, enabling precise control of auxiliary equipment and processes, as illustrated by these example applications:

- Switch circuits within AUT.

- Activate marking or stamping devices.

- Trigger PLC-controlled actions, such as laser scanning

- Control lighting and conveyor systems for binning

- Sort resistors by tolerance.

- Activate diverter gates on solar panel testing lines.

- Integrate a third party instrument for test augmentation.

- Control automated molding equipment.

- Trigger a visual or audible signal to indicate batch completion.

Several representative use cases are summarized in the following sections.

Applications: Horizontal Market

Fig. 1: CB35 Relay Board for I/O Control

Measurement of Capacitive Dissipation Factor

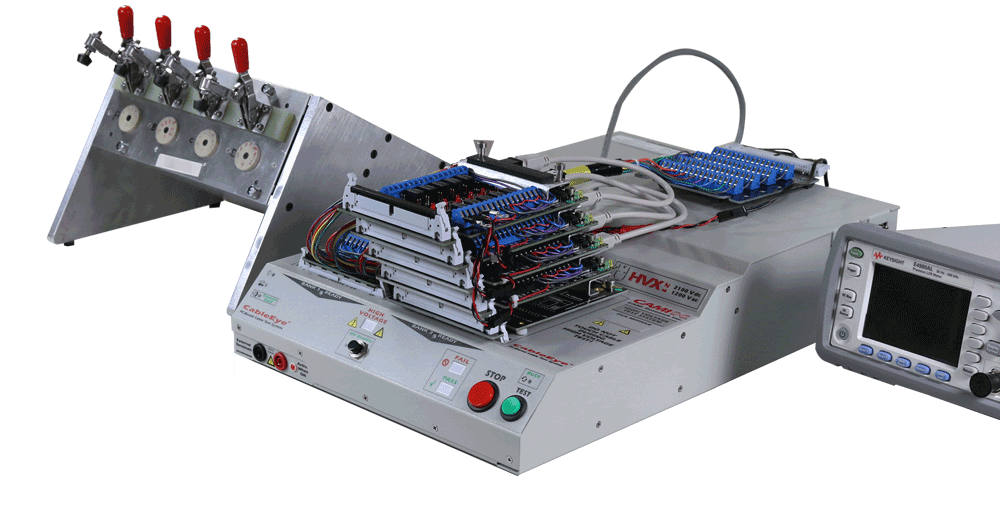

To meet the demanding requirements of aerospace testing, this advanced HVX-21 test system (Fig. 2) is configured to additionally check capacitive dissipation factors using a third party instrument (shown on the far right). Developed for Pacific Aerospace, the solution shows how the CB35 relay board enables enhancement of an already advanced measurement system by enabling seamless integration of additional measurement instrumentation.

The customer's test interface fixture (shown to the left of the tester) securely positions the Article Under Test using four clamps, aligning it with four contact disks, each with several electrical contacts. By leveraging a scalable stack of five CB35 relay boards, the system independently switches every contact with precision and repeatability. This modular relay architecture allows the setup to be mounted directly on the tester or deployed remotely, offering maximum flexibility in system design.

Two CB29 boards and custom software complete the solution, creating a powerful, automated test platform that delivers accurate results while adapting to complex aerospace test requirements.

Application: Aerospace

Fig. 2: Capacitive Dissipation Factor Measurement System

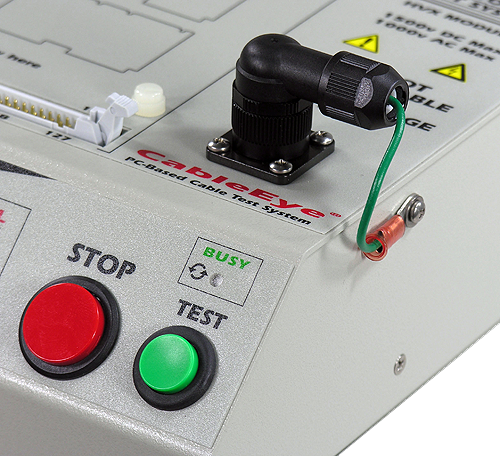

Activation of Lock and Release Latches

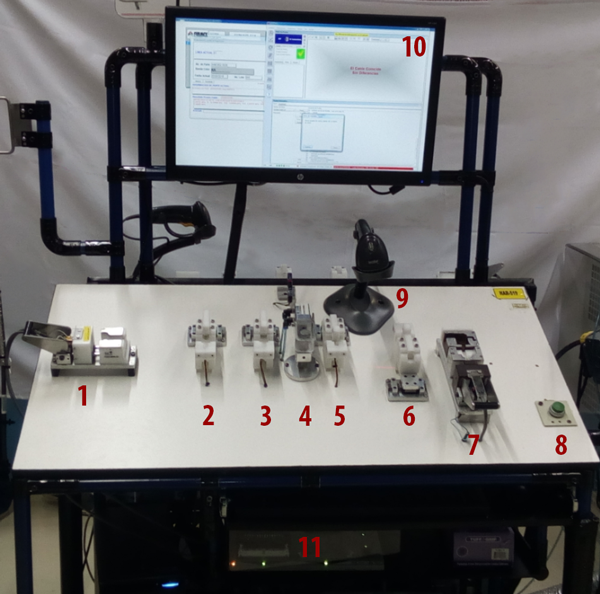

Furukawa has a smart test line of over 30 stations, each powered by a CableEye® tester (Fig. 3). The user interface is comprised of the CableEye graphical user interface (10), and a harness board fitted with continuity-test blocks (1 & 7), a lock and release latch (4), presence-test devices (1, 2, 3, 5, 6, 7), static barcode scanner (9), and test push-button (8). The test instrument itself remains ‘hidden’ beneath the harness board (11) and additionally checks for connection signals from the presence-test devices.

Continuity testing proceeds automatically once these devices detect simultaneous attachment and signal proper installation of the harness under test.

The lock & release latch is connected via a CB35 relay board, and receives a release signal from the tester only if the test yields a ‘pass’ result.

Application: Automotive

Fig. 3: Harness Test Station

Photo: Furukawa

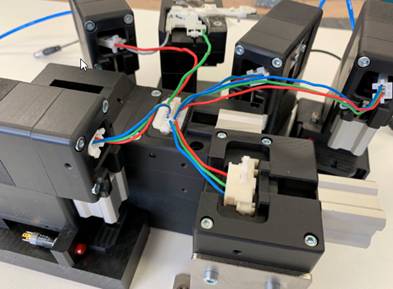

JST has a similar scenario (Figs. 4 to 6) and uses JavaScript to automate the process from verifying test-readiness and launching the electrical test, to printing a barcoded label and releasing the latch (if the AUT passes).

Application: Automotive

Fig. 4: Harness Test Station Without UUT Connected

Photo: JST

Fig. 5: Relay Board

Photo: JST

Fig. 6: Connection to Low Voltage Tester

Photo: JST

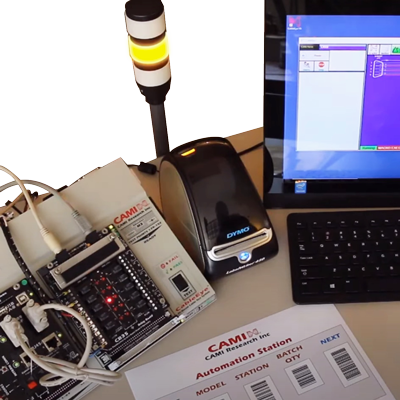

Activation of Tower Light as "Test in Progress" Indicator

During high-voltage testing, clearly indicating when a test is active can be considered critical for operator safety. In this setup, a tower light is used to provide a highly visible “Test in Progress” signal, alerting personnel that high voltage is present and access should be restricted.

For simple Pass/Fail indication, most tower lights can be connected directly to the Remote port of a CableEye tester. However, when an active safety warning is required, such as during high-voltage testing, the tower light is connected to a CB35/R relay board (Fig. 7). This allows the light to be automatically activated at the start of the test and deactivated when testing is complete, reinforcing safe operating practices.

Application: High Voltage Testing, Operator Safety in Horizontal Market

Fig. 7: Test in Progress Indicator

(Demonstration on M Series Tester)

Remote HV Activation

For customers who demand the highest level of safety, the HVX offers a remote high-voltage enable option that removes the need for direct operator interaction. Using a Macro or JavaScript-driven relay and the HVX remote control interface (Item 829X), high voltage can be enabled automatically, without ever touching the front panel.

In this end-user setup, a JavaScript briefly activates a relay on the CB35/R, mimicking the action of the front-panel Enable HV button through the Hirose remote control connector. This allows the HVX to be fully operated while enclosed in a cabinet or plexiglass safety enclosure.

By physically separating operators from high-voltage circuitry, this solution delivers peace of mind, enhances workplace safety, and supports compliance with strict safety protocols, ideal for labs and production environments where human exposure to high voltage must be minimized (Fig. 8).

Application: High Voltage Testing, Operator Safety in Horizontal Market

Fig. 8: Remote Control Interface (Item 829X)

Driving PCB Relays

A leading connectivity and automation technology manufacturer in France relies on the CB35 to streamline testing of PCBs. These boards are populated with connectors, diodes, resistors and relays. The CB35, in combination with a macro, is used to drive the relays of the PCB and the tester checks for proper function. (Fig. 10).

This automated approach ensures every relay operates correctly, improves test consistency, and supports high-quality production standards, delivering confidence in every assembled board.

Application: Switched Circuit Product for Horizontal Market

Fig. 10: CB35 Relay Board